INDUSTRY

Recreation

PROJECT

Design Build ECO Chill Ammonia Package

GENERAL CONTRACTOR

Northwest Contracting

PROJECT CONTACT

Drew Perryman, Account Manager

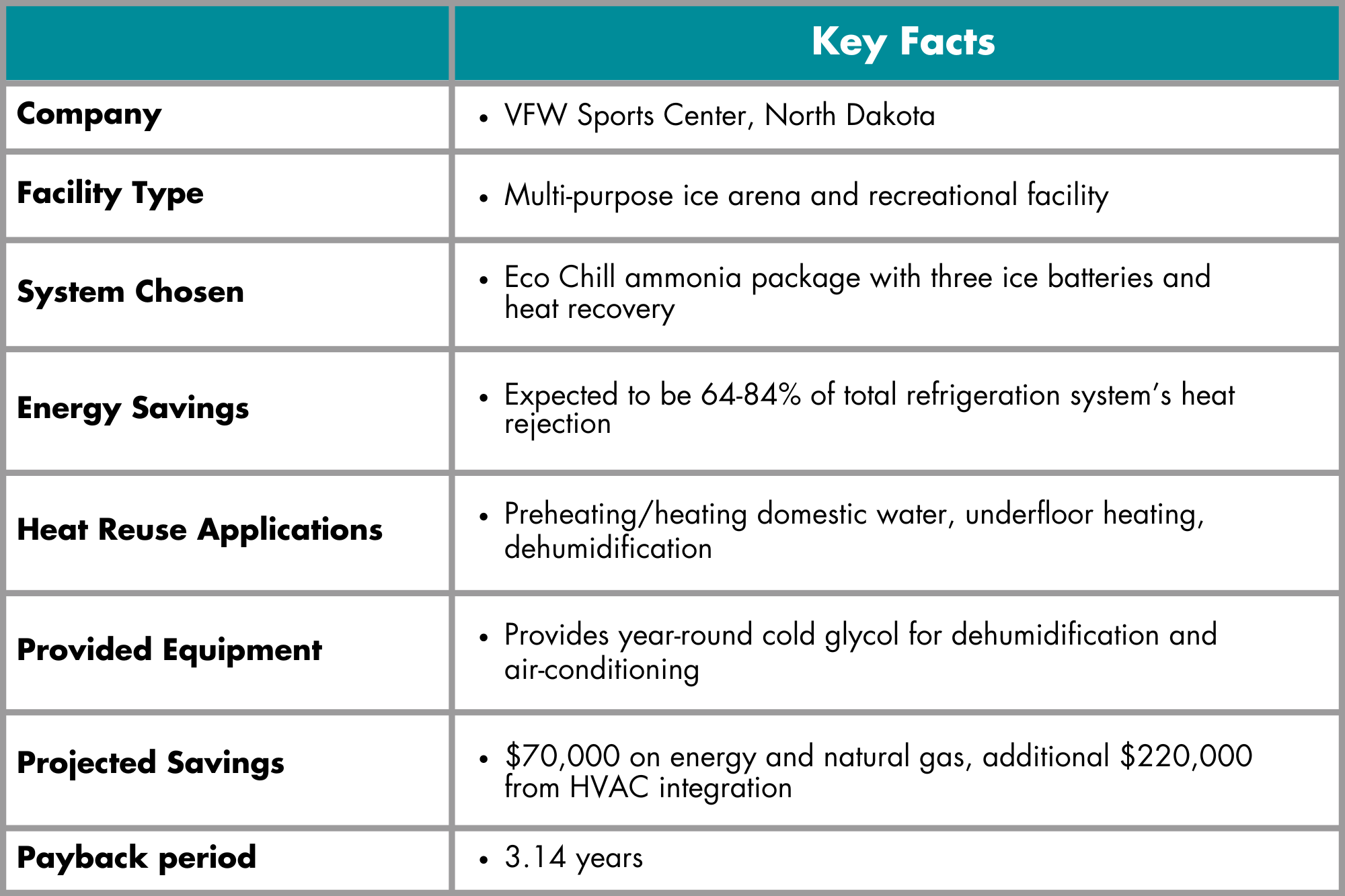

The VFW Sports Center is a multi-purpose ice arena and recreational facility in Bismarck, North Dakota (United States). It is owned and operated by the City of Bismarck’s Parks & Recreation Department and is home to the North American Hockey League’s Bismarck Bobcats team plus various other local teams and clubs – from figure skating to curling. It is also open for public skating.

The VFW arena opened in 1986 and a second sheet of ice was added in 1999. In 2022, the City of Bismarck approached CIMCO to design and install an additional third ice sheet for the facility.

CIMCO’s Eco Chill ammonia package complete with three ice batteries and heat recovery was chosen from four possible system options proposed.

Maximizing Savings with Heat Recovery

This design is expected to realize energy savings ranging from 64-84% of the total refrigeration system’s heat rejection. Savings are maximized with the addition of CIMCO’s Eco Sense control system, ensuring the heat recovered is used effectively throughout the facility. The main objective of this control system is to reuse as much of the heat reclaimed as possible, limiting the need for supplemental heat.

The rejected heat can be reused in many ways, including preheating and heating domestic water, underfloor heating, and dehumidification. An Eco Dry system was also added to provide year-round cold glycol for the ice rink’s dehumidification processes and air-conditioning requirements. This package offers a lower cost when compared to a mechanical fluorinated gas system with electricity and natural gas needs.

The custom-designed CIMCO Eco Dry solution can ventilate, heat, and control the air quality, also dehumidifying the ice rink area – all with a single unit. It is controlled by the Eco Sense system and fully integrates into the facility’s Building Management System (BMS).

The heat recovery is also integrated into the mechanical HVAC system to ensure the most efficient rink and building system.

Three ice batteries were included in the design to accomplish cooling during peak hours, providing a false load to the refrigeration system when heating is required for the Eco Dry but there is no load requirement for the ice.

Quick Return on Investment

Savings on energy and natural gas of $70,000 are projected, and the integration of HVAC to the system is expected to result in savings of another $220,000. As such, CIMCO calculated the payback period for the premium paid on the ECO Chill system as only 3.14 years.

This project is set for completion September 2024.

Related Posts

CIMCO Refrigeration’s New Facility in Bradford Strengthens Regional Service and Prefabrication Capabilities

CIMCO Expands Large-Scale Heat Pump Offerings Through Everllence Partnership

DesLaurier Cold Storage

|

|