Energy Efficiency at the Forefront:

The Shift from Natural Gas Boilers to Heat Pumps

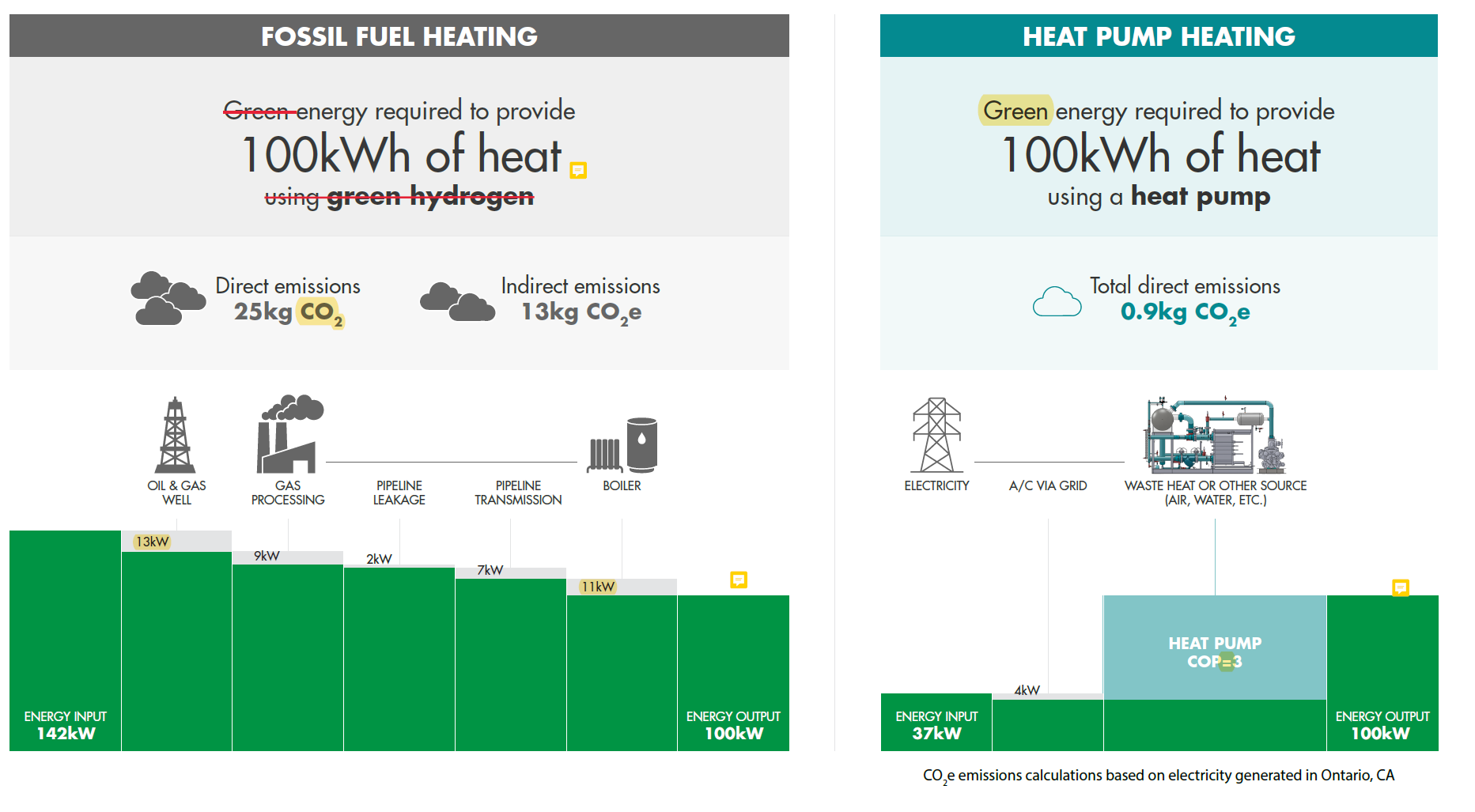

Natural gas boilers have long been popular in industrial, food, and beverage applications. However, the escalating prices of natural gas coupled with mounting concerns surrounding energy usage, emissions, and carbon taxes are prompting food and beverage facilities to explore more efficient and cost-effective alternatives. Introducing heat pumps—an increasingly compelling solution garnering widespread interest in North America for its efficiency and significant reduction in energy consumption. While natural gas boilers have a relatively low upfront cost and operate with around 90% efficiency, they still result in energy loss and high CO2 emissions throughout the extraction-to-distribution process. On the other hand, heat pumps function by harnessing energy from electricity and can achieve efficiencies of about 300%. Moreover, heat pumps emit significantly fewer emissions due to the low global warming potential of ammonia, which, coupled with its capability to generate at least three times more heat than natural gas boilers, underscores its environmental and efficiency advantages. |

What makes heat pumps the perfect fit for food and beverage processing?

Waste Heat: A Valuable Resource In conventional food plant processes, a substantial amount of heat is traditionally generated only to be dissipated into the atmosphere as waste. Coincidentally, these very food plants require significant volumes of hot water for essential wash-down procedures. Meeting this demand for hot water typically involves burning fossil fuels, a practice that not only releases emissions but also results in a considerable loss of efficiency. The introduction of ammonia heat pumps presents a sustainable solution to this challenge. These heat pumps efficiently capture and repurpose the otherwise wasted heat, converting it into a valuable resource for applications such as wash-down processes. The heat pumps not only minimize heat wastage but also mitigate the need for burning fossil fuels, contributing to both environmental sustainability and increased operational efficiency. Notably, the majority of processes in the food and beverage sector either currently operate at, or can be modified to operate at, temperatures between 50-90 °C (122-194 °F), making ammonia heat pumps particularly well-suited for these applications.

Coefficient of Performance (COP) of Industrial Heat Pumps The COP serves as a metric for gauging the efficiency of a heat pump. This efficiency is intricately linked to the temperature increase required – commonly referred to as the temperature lift. The relationship is straightforward: the greater the temperature lift between the heat source and the sink, the lower the efficiency or COP. A COP of 2 signifies that the heat pump delivers twice as much thermal energy as the electrical energy it consumes. In the case of industrial heat pumps, achieving high efficiency becomes feasible, especially with a COP exceeding 3, when the temperature lift falls within the range of 30-50 °C (86-122 °F). Notably, industrial heat pumps leveraging waste heat sources tend to exhibit particularly high COP values, often around 3-4, showcasing their adept usage of existing heat sources. |

Heat Pumps Meet Every Temperature Requirement in the Process

Project Spotlight:

Proven Savings at Maple Leaf Foods with CIMCO's Ammonia Heat Pump

Maple Leaf Foods in Brandon, Manitoba is a prime example of how switching to an ammonia heat pump can greatly reduce electricity use, cut down emissions, and accelerate a facility's journey to decarbonization. The plant processes 18,000 hogs per day, five days a week, and uses 140 °F (60 °C) water for up to 22 hours a day.

Traditionally, the process relied on natural gas boilers and direct-contact water heaters. By adding a heat pump function into the existing ammonia refrigeration system, Maple Leaf reduced its natural gas consumption by 3 million cubic meters annually, amounting to savings of $223,599 (per year).

Additional Resources

Article

Decarbonizing the Industrial Sector Through Natural Refrigerant Heat Pumps

Learn more