Suggestions to help decrease the risk of COVID-19 transmission between workers in close proximity on production lines

Reducing transmission of COVID-19 among workers: Decreasing risk for adjacent workers on production lines in a refrigerated process room

No matter which industry you consider, the COVID-19 pandemic has had a profound impact on businesses and their daily routine. As governments monitor the situation and provide updates globally and locally, organizations are coming to the realization that a return to the old ‘normal’ may not happen anytime soon (if at all) and new policies must be applied to adapt to the ‘new normal’. Safe work and risk mitigation practices are vital to slowing and preventing the spread of COVID-19. This is particularly crucial for those essential workplaces that operate in large facilities with production lines – such as food chain suppliers.

According to epidemiologic evidence, COVID-19 appears to transmit largely through respiratory droplets and contact. This suggests that transmission in a workplace setting can occur either directly, through close contact, or indirectly, through contaminated surfaces and/or objects. Sharing workstations or being in close proximity heightens this possibility, which means adjacent workers on productions line are particularly at risk.

Pulling from our years of experience in the refrigeration industry, we have compiled some suggestions as a guide to decrease the risk of SARS-COV transmission between workers in close proximity on production lines. It is important to note that this is a rapidly evolving situation; individuals and organizations are working on various methods to improve safety in these facilities, and newer solutions are being introduced continually. However, the options we present here can help increase hygiene levels for workers in facilities beyond the spread of COVID-19, and deserve deliberation for daily sanitation benefits too.

There are four types of solutions that can reduce the risk of transmission:

- Hygienic Roof Top Units (RTUs)

- Air Handling Units (AHUs)

- Exhaust Fans & Makeup Air Units (EFs & MAUs)

- Personal Protection Equipment (PPE)

Each comes with its own advantages to take into consideration. We hope to guide you through some of the main options in this document, but the team at CIMCO Refrigeration is always happy to hear from you and help provide a solution tailored to your facility.

- Personal Protection Equipment

PPE is a commonly used term at the present. The equipment consists of masks or respirators in combination with eye or full-face protection. These are fast, easy, and inexpensive to acquire, effective outside of work areas and provide an immediate solution to decreasing risk.

- Industrial Hygienic Roof Top Unit(s)

Industrial RTUs can provide clean air to workers with either fresh air makeup or by cleaning return air. Some of the main advantages include the fact that they can return air once HEPA filtration & potentially secondary lines of defence, such as UV, clean it. The supply ductwork can be designed to distribute clean air down to the work area, and return air can be designed to collect potentially contaminated air from workers, minimizing potential for cross-exposure between workers. It also provides heating, cooling, & dehumidifying of space as well as fresh air make-up, air exhaust, and cleaning of recirculated air.

- Air Handling Unit(s)

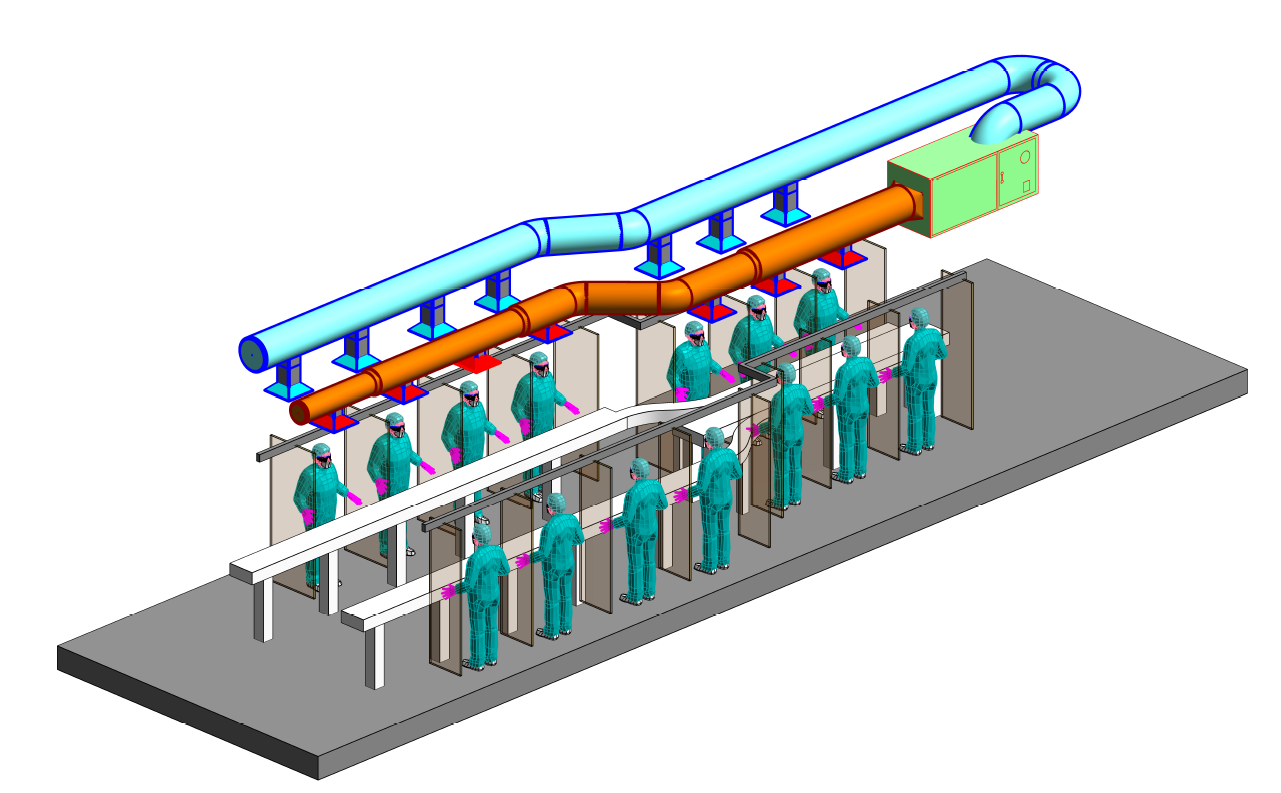

AHUs can come in various sizes – from very large central AHUs to individual workstation AHUs. Potentially contaminated air can be collected from the workers, cleaned, & returned directly to the room, which means there is no reliance on outdoor air. No additional refrigeration is typically required, and the supply air can be designed to distribute clean air directly to workers.

Central AHUs can serve entire rooms or a large number of workers. They can be roof mounted or hung in the room. Complete with return ducting, these are designed to draw air low from the workers’ area, clean the air, and then duct it back down to the workers’ area.

Multiple AHUs could serve a small group of workers; these would be hung in the room directly above workspace. The return ducting draws air from individual workers, cleans it and returns the air to individual workers.

Both central AHUs and small area AHUs can be designed to collect potentially contaminated air from workers, minimizing potential for cross-exposure between workers.

Individual workstation AHUs, as the name indicates, require one unit per worker. These could be floor-supported, moveable, and with built-in dividers for a physical barrier between workers.

- Exhaust Fans & Makeup Air Unit(s)

These may be used to supply tempered fresh air to the room. Some advantages include the fact that they are installed outside of the workspace, don’t require cleaning the air, and the cooling is done with either built-in cooling & heating capability, or refrigeration coil for both cooling and hot gas heating by connecting to the central refrigeration system. With the exhaust air ductwork in the room, roof-mounted Efs and MAUs can be combined with registers near the workers to reduce air change requirements. Be sure to take the additional cooling and humidity load into consideration, as it may be significant.

Considerations

There are several considerations for each of the solutions mentioned above that must be taken into account. These include structural requirements, installation time/disruption to operations, delivery times, availability of supplies, number of units required, other sanitation challenges, weight of the equipment, and cost of both installation and maintenance.

None of these solutions can prevent transmission of a virus, but they can heighten the sanitation levels in your facility to help your workers stay safe. These solutions are designed only for the process room; there are other common areas that must be adjusted accordingly. As with most instances, there is no single solution for mitigating risk in facilities. As we reopen businesses and start to establish the new normal, it is crucial to support the workers who risk their lives in the most effective way possible. This will depend on several factors, and to find the best solution we would recommend speaking to a specialist about your plant.

Related Posts

CIMCO Refrigeration’s New Facility in Bradford Strengthens Regional Service and Prefabrication Capabilities

CIMCO Expands Large-Scale Heat Pump Offerings Through Everllence Partnership

DesLaurier Cold Storage

|

|