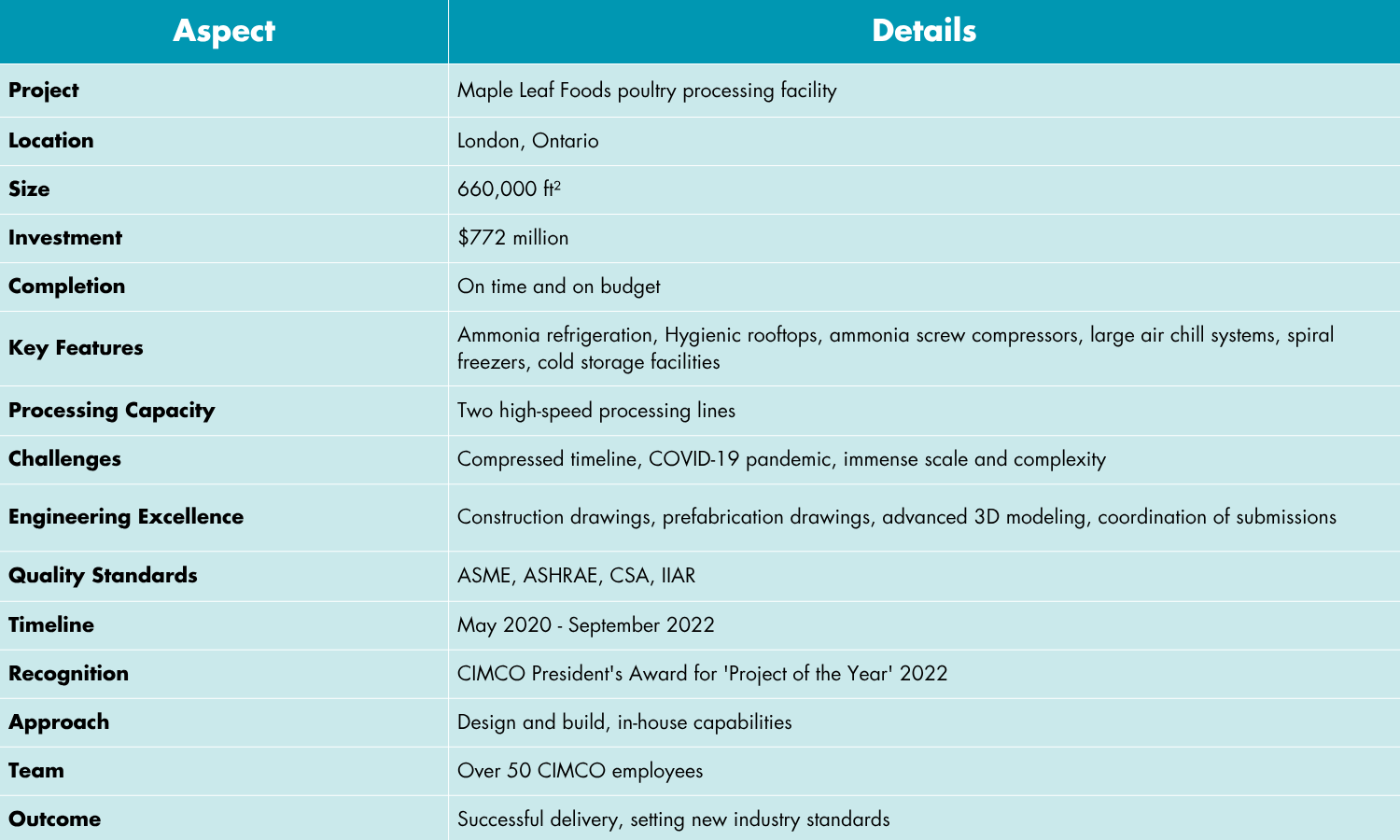

Scale Meets Experience

CIMCO was pleased to partner with Maple Leaf Foods’ project for what was, at the time, the largest single-site investment ever made in the Canadian food sector – it was a testament to CIMCO's reputation as a leader in the thermal space.

For decades, CIMCO has been Maple Leaf Foods’ key refrigeration partner, with a strong track record of completing quality jobs on time and on budget. “As a key partner to Maple Leaf Foods, CIMCO is committed to the organization's continued long-term success and growth,” said David Fauser, VP Sales, Marketing & Strategy at CIMCO.

This trust would prove crucial as the CIMCO team faced unprecedented challenges: a compressed timeline, execution during the COVID-19 pandemic's peak, and a project of immense scale and complexity.

“The sheer size of the project was remarkable,” notes Peter Reeve, Director of Engineering at CIMCO. The facility’s new ammonia refrigeration installation supports three different temperature levels which includes a large amount of equipment such as hygienic rooftops, large screw compressors, large air chill systems, spiral freezers, and cold storage facilities – all designed to handle two high-speed chicken lines.

Despite these challenges, the CIMCO team worked tirelessly to achieve the deadlines, raising the bar for thermal installations in the sector.

.png?sfvrsn=4baadf22_1)

Engineering Excellence in Action

The project involved over 50 CIMCO employees across various departments, showcasing the company's comprehensive in-house capabilities. The engineering team's expertise was particularly evident in their ability to adapt to changing priorities while maintaining strict quality standards.

CIMCO's engineering department demonstrated exceptional capabilities throughout the project:

- Production of hundreds of construction drawings;

- Creation and implementation of precise and advanced 3D modeling and prefabrication processes

- Coordination of hundreds of submissions among customers, sub-contractors, and construction crews.

Like the rest of the company, CIMCO's engineering team adheres to the highest quality standards, ensuring that each project meets all applicable laws, regulations, and codes. Its solid knowledge base includes ASME, ASHRAE, CSA, and IIAR.

Following the latest versions of all applicable codes, by-laws, and standards ensures that each project is completed to the highest standards. “Our commitment to quality means you can trust CIMCO to deliver reliable, efficient, and compliant engineering solutions,” said Reeve.

.png?sfvrsn=32aadf22_1)

Meeting Timelines Despite Pandemic

The project commenced in May 2020, during the height of the pandemic. Despite these extraordinarily challenging circumstances, CIMCO maintained its commitment to the customer’s timeline.

With approximately dozens of people on-site during peak construction and careful management of subcontractors, the team successfully met all major milestones, culminating in production startup in late September 2022.

“This was an important project for Maple Leaf Foods, and CIMCO made sure to bring our best expertise and resources to ensure the best quality and value for the project,” said Reeve.

.png?sfvrsn=1faadf22_1)

Recognition of Excellence

The Maple Leaf Foods project's success earned it the prestigious CIMCO President's Award for 'Project of the Year' in 2022, recognizing not only the technical achievement but also the team's commitment to CIMCO's core values.

“This year's winning team demonstrated exceptional collaboration, determination, and a commitment to success,” said CIMCO's President, Dave Malinauskas. “This project, the largest in CIMCO history, is a testament to CIMCO's dedication to innovation, sustainability, and customer satisfaction. It is a significant investment in the sustainable and ethical future of fresh poultry processing and is a deserving winner.”

.png?sfvrsn=62addf22_1)

One Partner, Total Solution

As North America's largest industrial contractor, CIMCO sets itself apart through a unique "design and build" approach that integrates all aspects of thermal projects under one roof. From design to commissioning, every project component is handled in-house, including automation/ control systems and starter/ motor control panels – capabilities that distinguish CIMCO from typical contractors.

"We take all your needs, challenges, and considerations into account," explained Fauser. "Be it precise temperature requirements, equipment footprint, load calculation, or selection of equipment, CIMCO ensures all thermal needs are met efficiently and effectively."

.png?sfvrsn=cdaadf22_1)

This comprehensive approach leverages CIMCO's in-house advantages, such as skilled refrigeration engineers for equipment selection and sizing, dedicated CAD and engineering groups for controls and documentation, and integrated prefabrication facilities. The result is a streamlined solution that saves customers time and resources while enabling the project team to adapt quickly to changing priorities.

The Maple Leaf Foods project demonstrates the power of this integrated approach in action. While the engineering group produced crucial documentation and the CAD team managed controls to keep site work flowing smoothly, CIMCO simultaneously coordinated several large subcontractors handling specialized sheet metal, stainless steel, insulation, and wiring work. This orchestration of multiple complex services under one cohesive team proved essential to the project's success.

“Through intelligent design and state-of-the-art engineering, CIMCO continues to ensure long-term performance with minimal downtime for its customers, setting new industry standards,” said Fauser.

.png?sfvrsn=a4aadf22_1)

Ready for the Future

The successful delivery of Maple Leaf Foods' landmark facility demonstrates that CIMCO's comprehensive capabilities extend far beyond traditional thermal solutions. Through seamless integration of design, prefabrication, and on-site execution, the project team transformed a complex vision into reality, despite the unexpected challenges.

As customers seek partners who can deliver increasingly sophisticated projects under demanding conditions, CIMCO stands ready. With proven processes, in-house expertise, and a track record of delivering Canada's most ambitious thermal projects, CIMCO continues to shape the future of industrial refrigeration.

Related Posts

Industrial Heat Pumps are the Past, Present and Future

Interconnected Efficiency: Leveraging Ammonia Heat Pumps for Sustainable Manufacturing