"We are happy with our decision to go with a CO2 system at our Calgary facility. System reliability, durability, and safety are key factors in our decision to go with CO2 for the Calgary installation. If the system continues to perform well, we will consider expanding our western region systems in the future.”

Gavin Sargeant

Executive Vice President of Conestoga.

Overview

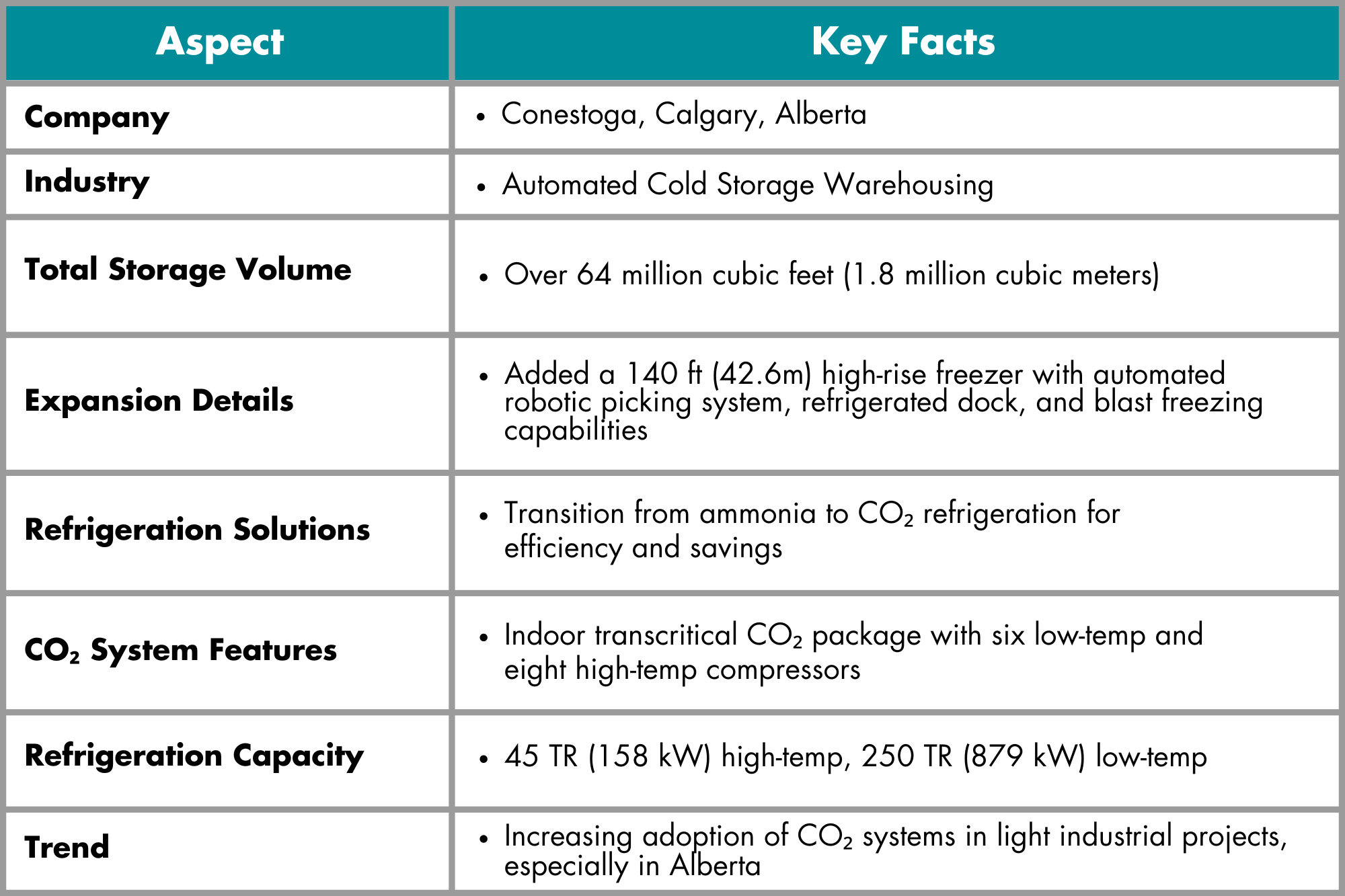

Serving customers from across Canada and around the world, Conestoga operates five automated cold storage warehouses with a total storage volume of over 64 million cubic feet (1.8 million cubic meters). It provides fully computerized warehouse facilities, distribution centers, and a chain of cross docks that enable them to deliver products efficiently from coast to coast.

One of these automated cold storage warehouses is in Calgary, AB (Canada). To expand its business in this region, Conestoga recently increased its freezer storage capacity and handling capabilities at this facility. A 140 ft (42.6m) tall high-rise freezer with a fully automated robotic picking system, refrigerated dock, and blast freezing capabilities were added to the existing facility.

Choosing CO2 for Savings

Conestoga has traditionally used ammonia refrigeration solutions at all its facilities. Even at the existing Calgary facility where the high-rise freezer was added, the rest of the holding freezer and facility is served by a recirculated ammonia system.

CIMCO Refrigeration (CIMCO) previously worked with Conestoga, installing an ammonia system for a similar high-rise freezer tower in Ontario. So, when the time came to expand the Calgary facility, CIMCO was called in to tender a suitable solution.

Initially, the customer had planned to install another ammonia system. However, this was around the time when CO2 started becoming more prevalent in the industrial space – especially in places like Alberta with favorable lower ambient conditions. Based on annual weather, it is assumed that a CO2 system in Alberta would be able to operate in a subcritical mode for most of the year, allowing for great efficiencies. This made CO2 a worthy contender for this industrial project that would usually default to using ammonia.

To compare solutions, CIMCO proposed a DX ammonia system as well as a transcritical DX CO2 system for the Calgary freezer, providing an energy analysis between the two systems. The customer ultimately decided to go with the more efficient CO2 option as it proved to be the best choice for this particular location.

It was projected that CO2 could provide annual energy savings versus the comparable ammonia option.

“A key deciding factor was the fact that the customer wouldn’t have to pay a huge premium on the CO2 system,” explained Ryan Ferguson, Team Lead Capital Projects, Western Canada at CIMCO. “This could easily be paid back over the lifetime of the system thanks to the efficiency gains.

The Solution

CIMCO then designed and installed one of the first high-rise freezers for a distribution warehouse to use CO2. It serves the 22,930 ft2 (2,130 m2) of freezer space as well as the 20,634 ft2 (1,917 m2) dock/ staging area. The new system was started in March 2022.

The system is an indoor transcritical CO2 package, complete with six low-temperature compressors and eight high-temperature compressors. This results in a refrigeration capacity of 45 TR (158 kW) on high-temp and 250 TR (879 kW) on low-temp.

As the engine room was on ground level with the penthouse evaporators at the top of the facility, the CIMCO team had to overcome the challenge of getting all the CO2 piping to the roof. Subsequently, they constructed a piping rack on the ground to build, insulate and pressure test the piping before craning it onto the roof. A man-lift was needed to weld all the piping joints. After everything was completed and in place, another pressure test was run on the full system.

At CIMCO, quality is of utmost importance and the team goes out of its way to ensure all installations are compliant and safe. CO2 high-pressure piping is designed to meet the American Society of Mechanical Engineers (ASME)’s B31.5 Refrigeration Piping and Heat Transfer Components code requirements and is also registered with ABSA (Alberta Boiler Safety Association). It is then installed and pneumatically pressure tested according to CIMCO’s ABSA-certified quality management system to ensure a safe, proper installation based on the required working pressures.

“Once everything got up and running, the plant performed very well and the customer was happy with their choice of opting for CO2,” said Ferguson.

"We are happy with our decision to go with a CO2 system at our Calgary facility,” said Gavin Sargeant, Executive Vice President of Conestoga. ‘We are hopeful the projected energy savings will be realized in the long term. System reliability, durability, and safety are key factors in our decision to go with CO2 for the Calgary installation. If the system continues to perform well, we will consider expanding our western regions systems in the future.”

CO2’s Future in Industrial Applications

Conestoga has plans to expand the existing freezer capacity in the future and has made provisions to accommodate the CO2 equipment. Preliminary steel has been put in place to support another penthouse evaporator as well as piping lines for a second CO2 rack and gas cooler.

“Although bigger industrial facilities still predominantly use ammonia, there is a break-even capacity where CO2 starts making financial sense,” according to Ferguson. This varies based on the facility and the climate of its environment. “However, there is a noticeable trend toward increasingly using CO2 in light industrial projects, especially in places like Alberta.”

“CO2 is definitely picking up,” said Ferguson. “Especially on greenfield projects. CO2 comes up in virtually every proposal now. It is also becoming noticeably more affordable to choose CO2, which is expected to drive growth.”

Related Posts

CIMCO Refrigeration’s New Facility in Bradford Strengthens Regional Service and Prefabrication Capabilities

CIMCO Expands Large-Scale Heat Pump Offerings Through Everllence Partnership

DesLaurier Cold Storage

|

|